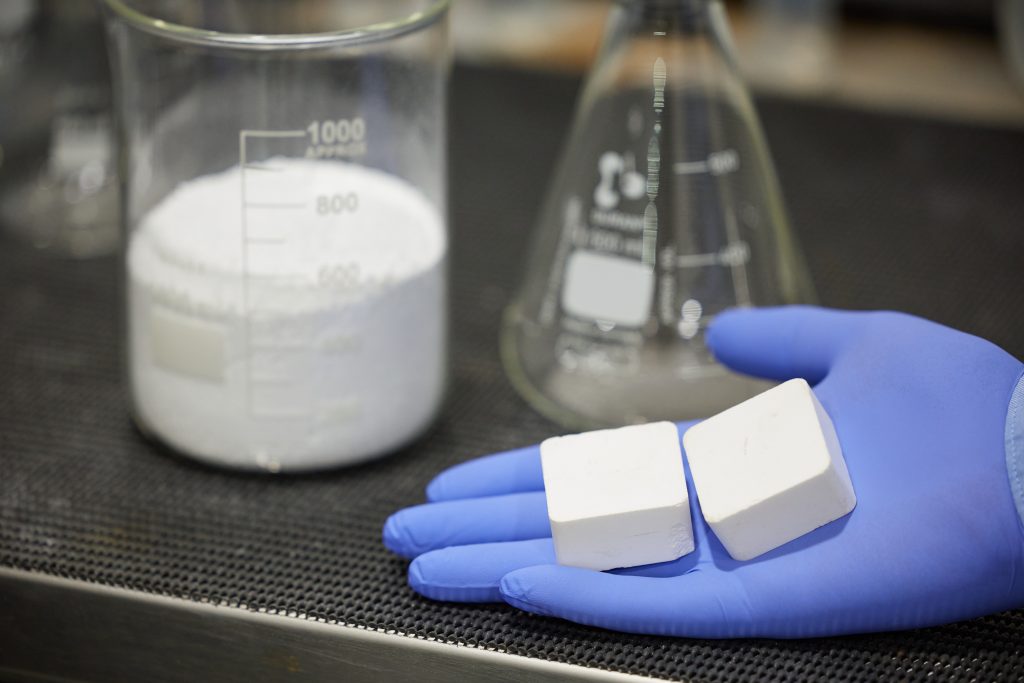

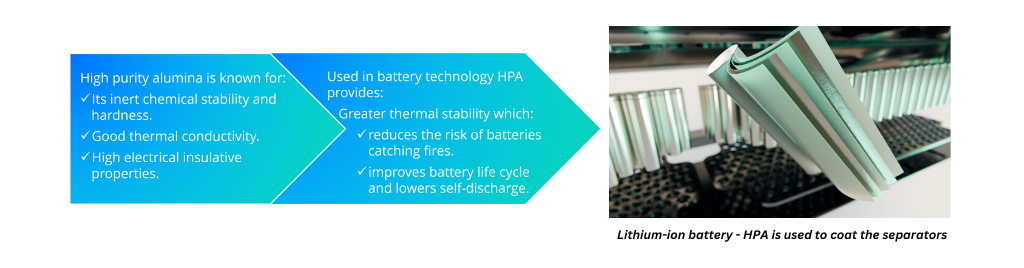

HPA is high in purity and therefore high in value. It is known for its inert chemical stability and hardness, and good thermal conductivity, yet high electrical insulative properties.

These characteristics make it a highly sought after product for use in lithium-ion batteries, LED lighting and advanced electronics such as iPhones, smartwatches, screens and semiconductors.

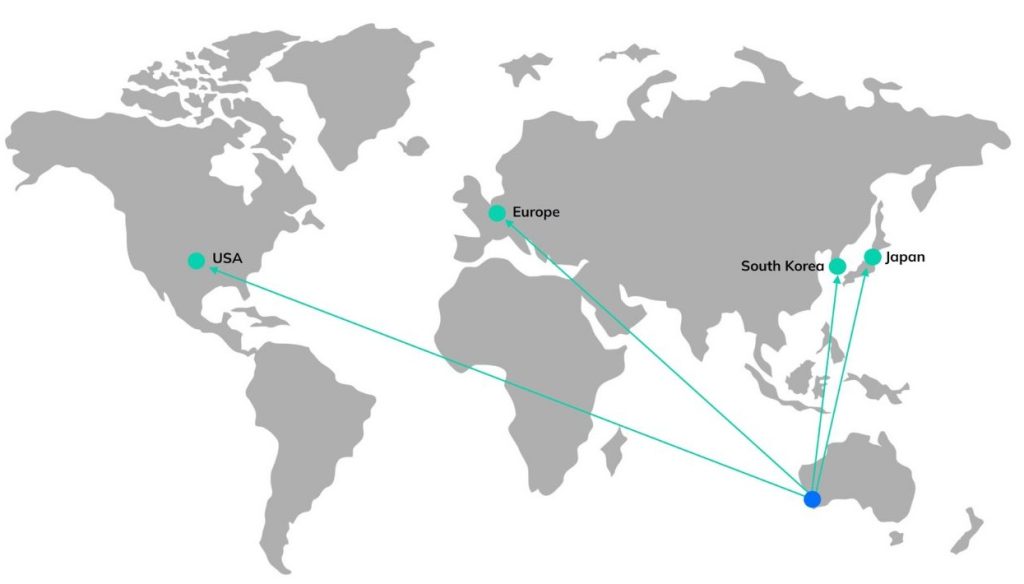

HPA market growth is driven by consumer demand for advanced electronics and clean energy technologies. This has seen year-on-year growth in the HPA market worldwide. This growth is expected to continue in line with global trends for technology that is more energy efficient, less carbon intensive, portable and better connected.